Part 1 – Thermal Growth

June 2, 2016

Round Corner Metal Rectangular Expansion Joint (New)

December 18, 2014Metal rectangular expansion joints with round corners and U-profiles significantly out-perform any other corner style, as demonstrated by this video. The more flexible a bellows, the higher its fatigue life. This video is of interest to design and maintenance engineers. This is a video that is of interest to design and maintenance engineers. Length: 0.57

Read More

Camera Corner Bellows

September 5, 2014Camera corner metal rectangular expansion joints have proven to be problematic for end users. The design requires considerable amounts of welding in the corners which are a stress riser during deflection. In addition the tight pitch of the profile more easily traps debris. This is a video that is of interest to design, piping, vessel

Read More

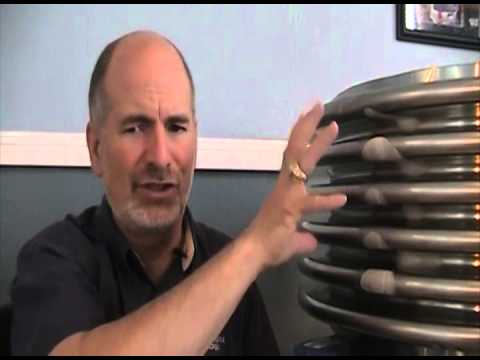

Inspecting Metal Bellows Damage

August 1, 2014A metal bellows can be easily damaged if installers are not careful. The dents, arc strikes, and scratches are not always a cause for immediate panic. This is a video that is of interest to maintenance engineers, inspectors, pipefitters, and contractors. Length: 3:37

Read More

Lugs on Pipe and Vessels *NEW*

November 30, 2015Load bearing lugs generate local bending stresses on thin walled shells such as pipe or vessels; these stresses can easily be reduced by optimizing the material arrangement. There are several methods for calculating the shell stresses which are covered in publications on the theory of plates and shells. This short video introduces visual concepts on

Read More

Acid condensate on metal bellows expansion joint

May 26, 2014High temperature flue gas ducting often has metal bellows expansion joints that are internally insulation. Make sure the bellows remains above 400F to prevent acids from condensating and causing corrosion failures This is a video that is of interest to design and maintenance engineers. Length: 1.33 (Click image to launch video)

Read More

Edge Welded Bellows *NEW*

September 5, 2014Edge welded metal bellows provide large movements with very low spring rates in round or rectangular ducting systems. This style is can be designed in short over all lengths. This is a video that is of interest to design and maintenance engineers. Length: 0.57 (Click image to launch video)

Read More

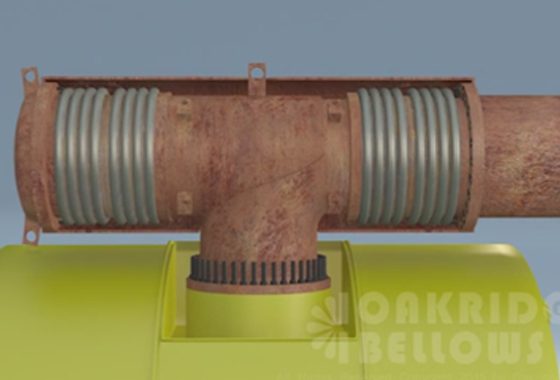

Metal Rectangular Expansion Joints

August 1, 2014Are all metal rectangular expansion joints created equal? Not even close. Many after-market metal rectangles are made with a V-profile with a miter weld at the corners – these are flawed design features. The longest lasting designs have a U-profile with round corners. This is a video that is of interest to design and maintenance

Read More

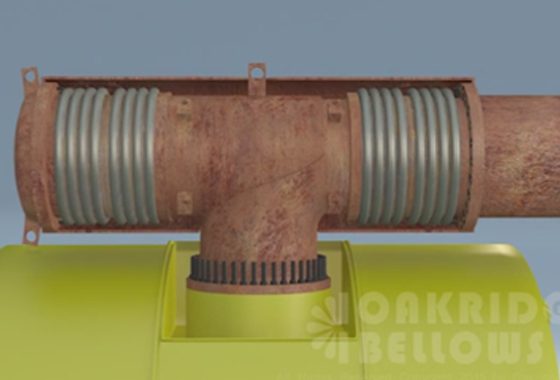

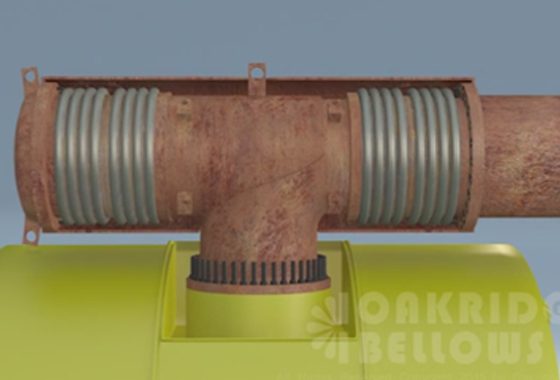

Expansion Joint Liners

August 1, 2014

Van Stone Flanges

August 1, 2014

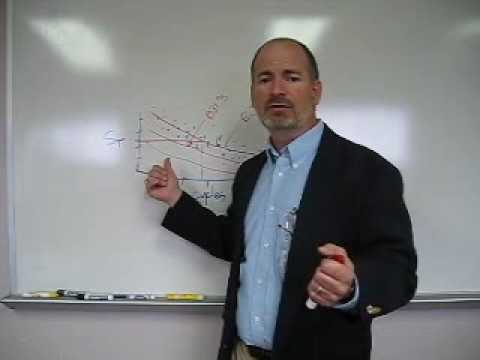

EJMA verses ASME

August 1, 2014The EJMA design guide and the ASME code have different design criteria for metal bellows cycle life. The history of the ASME B31.3, Section VIII, and EJMA fatigue curves are discussed along with practical recommendations for expansion joint cycle life specifications. This is a video that is of interest to design, piping, and vessel engineers.

Read More

Power Plant How a steam turbine cross over expansion joint works

January 13, 2018There is no excerpt because this is a protected post.

Read More

Power Plant How a steam turbine cross over expansion joint works

September 4, 2015There is no excerpt because this is a protected post.

Read More

Power Plant Steam Extraction Expansion Joints

October 31, 2014There is no excerpt because this is a protected post.

Read More

Power Plant Coal Pulverizer Ducting Expansion Joints

January 13, 2018There is no excerpt because this is a protected post.

Read More

Power Plant Steam Turbine Cross Over Expansion Joint

October 31, 2014There is no excerpt because this is a protected post.

Read More

Power Plant 2-Ply Testable Bellows For Steam Turbines

January 13, 2018There is no excerpt because this is a protected post.

Read More

Power Plant 2-Ply Testable Bellows For Steam Turbines

October 31, 2014There is no excerpt because this is a protected post.

Read More

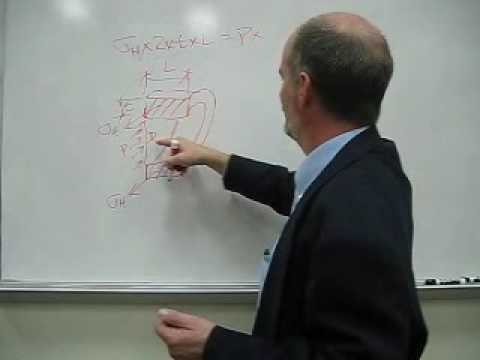

Why An Expansion Joint Works Part One

August 1, 2014How does a thin bellows hold the same pressure as that of a thicker pipe? The hoop stress pressure of a pipe is derived and then a comparison is made to how it is calculated for a metal bellows. This is the basis for the equation found in both the ASME code and the EJMA

Read More

Why An Expansion Joint Works Part Two

August 1, 2014

Metal Expansion Joint Installation

August 1, 2014

Steam Extraction Expansion Joints

August 1, 2014There is no excerpt because this is a protected post.

Read More