Metallurgy Of Metal Bellows Failures

July 9, 2014The Secret Life of Your Metallurgist Having more fun than you know, but at your expense The disturbing underworld So I accidently wandered into a Metallurgist convention at a hotel where I was staying. It was noisy and they were having an open mic joke hour. “Why couldn’t the metallurgist buy any snacks?”, I heard

Read More

Insider Secrets To Expansion Joint Repair

July 9, 2014Proceed with care I guess I should give the obligatory warning statement about how weld repairing bellows is specialized: it should only be attempted by professionals, don’t run with scissors, yadda, yadda. All true, but we both know end-users will, can, and have weld repaired thin gauge bellows, some with success and some with consequential

Read More

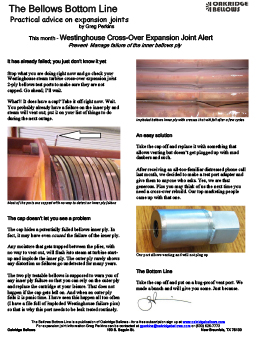

Westinghouse Tap Caps

October 10, 2017Westinghouse Cross-Over Expansion Joint Alert Prevent Manage failure of the inner bellows ply It has already failed; you just don’t know it yet Stop what you are doing right now and go check your Westinghouse steam turbine cross-over expansion joint 2-ply bellows test ports to make sure they are not capped. Go ahead; I’ll wait.

Read More

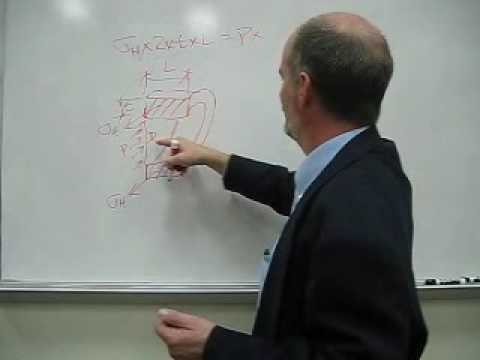

Why An Expansion Joint Works Part One

August 1, 2014How does a thin bellows hold the same pressure as that of a thicker pipe? The hoop stress pressure of a pipe is derived and then a comparison is made to how it is calculated for a metal bellows. This is the basis for the equation found in both the ASME code and the EJMA

Read More

Why An Expansion Joint Works Part Two

August 1, 2014

Metal Expansion Joint Installation

August 1, 2014

2-Ply Testable Bellows

August 1, 2014Many users such as power plants and refineries have expansion joints with 2-ply testable bellows. These redundant bellows are often overlooked during the piping system inspection. A demonstration is provided with a recommended test fixture for safe and easy testing between the bellows plies. This is a video that is of interest to maintenance engineers

Read More

Steam Extraction Expansion Joints

August 1, 2014There is no excerpt because this is a protected post.

Read More

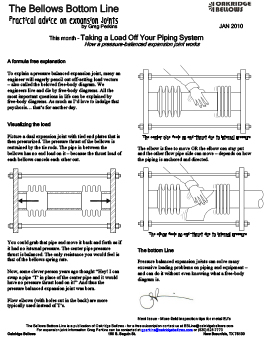

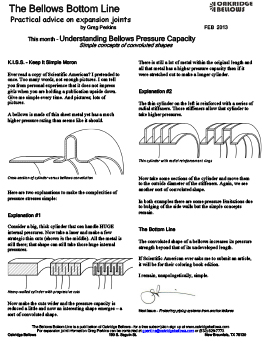

Understanding Bellows Internal Pressure

July 12, 2014Understanding Bellows Pressure Capacity Simple concepts of convoluted shapes K.I.S.S. – Keep It Simple Moron Ever read a copy of Scientific American? I pretended to once. Too many words, not enough pictures. I can tell you from personal experience that it does not impress girls when you are holding a publication upside down. Give me

Read More

Metal Bellows Cycle Life – EJMA vs ASME

July 12, 2014Will the real cycle life please stand up How can three well-respected codes, or design guides, not even be in the same ballpark when it comes to predicting bellows cycle life? On a recent bellows design the EJMA (Expansion Joint Manufacturers Association) curve gave a 7000 cycle rating; B31.3 gave 1150 cycles; and Section VIII/Appendix

Read More