Flanges On Expansion Joints (*NEW)

Low metabolism, poor self-image, or just bored?

Let’s just state what we’re all thinking – flanges are the fatsos of fittings. Oh come on, stop acting like I’m Joan Rivers; it’s so obvious and somebody had to say it.

OK, so that’s insensitive. The question is; why is that flange such a large chunk of steel?

That flange and bolting not only has to a) hold the piping together against the pressure thrust force b) crush a gasket for sealing, but to ALSO c) transfer any bending loads from one side to the next. Give those forgings a break; they can’t help their size, it’s not their fault.

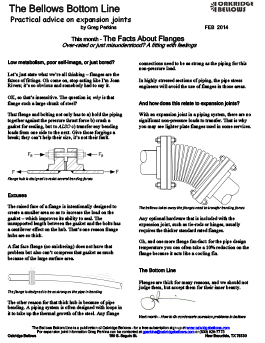

Flange hub is designed to resist several bending forces

Excuses

The raised face of a flange is intentionally designed to create a smaller area so as to increase the load on the gasket – which improves its ability to seal. The unsupported length between the gasket and the bolts has a cantilever effect on the hub. That’s one reason flange hubs are so thick.

A flat face flange (no snickering) does not have that problem but also can’t compress that gasket as much because of the large surface area.

The flange is designed to be as strong as the pipe in bending

The other reason for that thick hub is because of pipe bending. A piping system is often designed with loops in it to take up the thermal growth of the steel. Any flange connections need to be as strong as the piping for this non-pressure load.

In highly stressed sections of piping, the pipe stress engineers will avoid the use of flanges in those areas.

And how does this relate to expansion joints?

With an expansion joint in a piping system, there are no significant non-pressure loads to transfer. That is why you may see lighter plate flanges used in some services.

The bellows takes away the flanges need to transfer bending forces

Any optional hardware that is included with the expansion joint, such as tie-rods or hinges, usually requires the thicker standard rated flanges.

Oh, and one more flange fun-fact: for the pipe design temperature you can often take a 10% reduction on the flange because it acts like a cooling fin.

The Bottom Line

Flanges are thick for many reasons, and we should not judge them, but accept them for their inner beauty.