Moving Laterally in an Axial World

Going in another direction

Henry David Thoreau once wrote, “If a man does not keep pace with his companion, perhaps it is because he hears a different drummer,” to which his father promptly responded “Hey, drummer boy! Get your beatnik friends out of my house and go get a job!”

Many types of expansion joints only absorb axial movement such as externally pressurized, flanged and flued, and slip-packed styles. A metal bellows is the non-conformist of these piping components – it can also be moved laterally.

How it does what it does

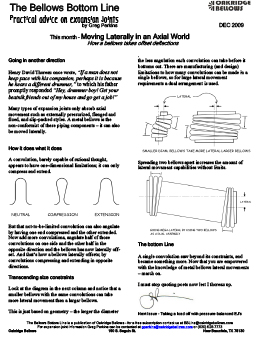

A convolution, barely capable of rational thought, appears to have one-dimensional limitations; it can only compress and extend.

But that not-to-be-limited convolution can also angulate by having one end compressed and the other extended. Now add more convolutions, angulate half of those convolutions on one side and the other half in the opposite direction and the bellows has now laterally off- set. And that’s how a bellows laterally offsets; by convolutions compressing and extending in opposite directions.

Transcending size constraints

Look at the diagram in the next column and notice that a smaller bellows with the same convolutions can take more lateral movement than a larger bellows.

This is just based on geometry – the larger the diameter

. the less angulation each convolution can take before it bottoms out. There are manufacturing (and design) limitations to how many convolutions can be made in a single bellows, so for large lateral movement requirements a dual arrangement is used.

Spreading two bellows apart increases the amount of lateral movement capabilities without limits.

The bottom Line

A single convolution saw beyond its constraints, and became something more. Now that you are empowered with the knowledge of metal bellows lateral movements – march on.

I must stop quoting poets now lest I thoreau up.