Why An Expansion Joint Works – Part II

The bellows exposed

There’s no mystery as to why a bellows can flex – it’s convoluted for crying out loud. This could be one short article. Except here’s the tantalizing part; when the bellows material flexes, the stresses shoot well into the plastic range.

At this point the collective mechanical engineering community gasps, women faint, dogs bark throughout the neighborhood.

Deflection stresses

The engineering schools taught us that if material yielded, it failed. Sure, exceptions were probably noted but it wasn’t covered on the test and ergo it didn’t exist.

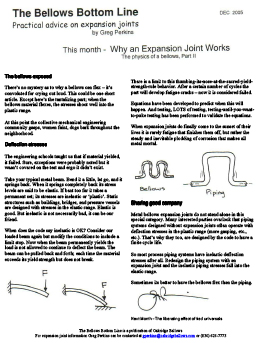

Take your typical metal beam. Bend it a little, let go, and it springs back. When it springs completely back its stress levels are said to be elastic. If bent too far it takes a permanent set; its stresses are inelastic or ‘plastic’. Static structures such as buildings, bridges, and pressure vessels are designed with stresses in the elastic range. Elastic is good. But inelastic is not necessarily bad, it can be our friend.

When does the code say inelastic is OK? Consider our loaded beam again but modify the conditions to include a limit stop. Now when the beam permanently yields the load is not allowed to continue to deflect the beam. The beam can be pulled back and forth; each time the material exceeds its yield strength but does not break.

There is a limit to this thumbing-its-nose-at-the-sacred-yield-strength-rule behavior. After a certain number of cycles the part will develop fatigue cracks – now it is considered failed.

Equations have been developed to predict when this will happen. And testing, LOTS of testing, testing-until-you-want-to-puke testing has been performed to validate the equations.

When expansion joints do finally come to the sunset of their lives it is rarely fatigue that finishes them off, but rather the steady and inevitable plodding of corrosion that makes all metal mortal.

Sharing good company

Metal bellows expansion joints do not stand alone in this special category. Many interested parties overlook that piping systems designed without expansion joints often operate with deflection stresses in the plastic range (more gasping, etc., etc.). That’s why they too, are designed by the code to have a finite cycle life.

So most process piping systems have inelastic deflection stresses after all. Redesign the piping system with an expansion joint and the inelastic piping stresses fall into the elastic range.

Sometimes its better to have the bellows flex than the piping.