Vanstone Flanges On Bellows Expansion Joints

A new twist on an old product

Sometimes there are such great ideas that when you see them you think “I could’ve thought of that”. The ideas I put in that category are – the wrist rocket, the slap chop, TiVo, and the van-stone flange. I could’ve thought up all of those… OK, maybe not TiVo – but definitely the other three.

Field fit-up

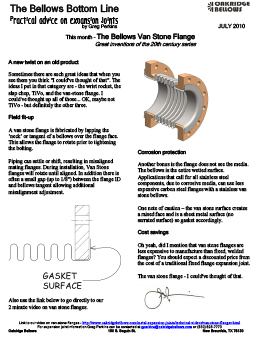

A van stone flange is fabricated by lapping the ‘neck’ or tangent of a bellows over the flange face. This allows the flange to rotate prior to tightening the bolting.

Piping can settle or shift, resulting in misaligned mating flanges. During installation, Van Stone flanges will rotate until aligned. In addition there is often a small gap (up to 1/8″) between the flange ID and bellows tangent allowing additional misalignment adjustment.

Also use the link below to go directly to our 2 minute video on van stone flanges.

Corrosion protection

Another bonus is the flange does not see the media. The bellows is the entire wetted surface. Applications that call for all stainless steel components, due to corrosive media, can use less expensive carbon steel flanges with a stainless van stone bellows.

One note of caution – the van stone surface creates a raised face and is a sheet metal surface (no serrated surface) so gasket accordingly.

Cost savings

Oh yeah, did I mention that van stone flanges are less expensive to manufacture than fixed, welded flanges? You should expect a discounted price from the cost of a traditional fixed flange expansion joint.

The van stone flange – I could’ve thought of that.