Externally Pressurized Expansion Joints

Don’t buckle under pressure

For large axial growth, a long bellows with lots of convolutions is needed for all that axial movement. Unfortunately a long bellows will buckle or ‘squirm’ easily when internally pressurized.

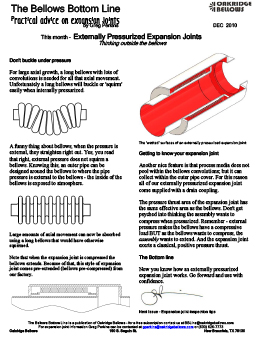

A funny thing about bellows, when the pressure is external, they straighten right out. Yes, you read that right, external pressure does not squirm a bellows. Knowing this, an outer pipe can be designed around the bellows to where the pipe pressure is external to the bellows – the inside of the bellows is exposed to atmosphere.

Large amounts of axial movement can now be absorbed using a long bellows that would have otherwise squirmed.

Note that when the expansion joint is compressed the bellows extends. Because of that, this style of expansion joint comes pre-extended (bellows pre-compressed) from our factory.

Getting to know your expansion joint

Another nice feature is that process media does not pool within the bellows convolutions; but it can collect within the outer pipe cover. For this reason all of our externally pressurized expansion joint come supplied with a drain coupling.

The pressure thrust area of the expansion joint has the same effective area as the bellows. Don’t get psyched into thinking the assembly wants to compress when pressurized. Remember – external pressure makes the bellows have a compressive load BUT as the bellows wants to compress, the assembly wants to extend. And the expansion joint exerts a classical, positive pressure thrust.

The Bottom line

Now you know how an externally pressurized expansion joint works. Go forward and use with confidence.